The Brutal Reality of Temperature Control

When you’re shipping perishables across a continent with temperature swings from -40°F to 110°F, you’re fighting physics every mile of the journey. I’ve seen entire truckloads of premium beef ruined because a reefer unit failed in Nebraska during a heatwave. $75,000 gone in hours.

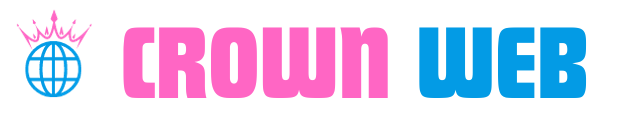

The cold chain in North America is a massive, interconnected system of refrigerated warehouses, specialized vehicles, monitoring technology, and trained personnel – all working to maintain specific temperatures across thousands of miles and multiple handling points.

Not All Cold Is Created Equal

Most people don’t realize there’s a world of difference between shipping ice cream, fresh fish, and vaccines. Each requires not just different temperatures but different handling protocols:

- Frozen goods (-0°F to -20°F): Ice cream, frozen meals, certain meats

- Deep frozen (-20°F and below): Premium seafood, certain medical supplies

- Standard refrigerated (33°F to 39°F): Dairy, produce, meat

- Cool chain (45°F to 55°F): Some pharmaceuticals, certain fruits

- Controlled room temperature (59°F to 77°F): Specific medications

A strawberry shipper I worked with lost $40,000 in product because the carrier set the reefer at 34°F instead of 36°F. That tiny difference froze the cell structures and turned perfect berries to mush.

The Infrastructure Backbone

The Canadian Side

Canada’s cold chain has unique challenges. With major population centers stretched along the US border and vast distances between them, Canadian carriers have developed some impressive solutions.

Toronto, Montreal, and Vancouver serve as the primary cold chain hubs, with state-of-the-art facilities from companies like VersaCold and Conestoga Cold Storage. But it’s the regional connections that make things interesting.

In the Maritimes, companies like Midland Transport have specialized in seafood movement for decades, with precise temperature monitoring to maintain quality of lobster and scallops bound for US markets.

The Prairie Provinces rely heavily on rail for long-haul cold chain movement, with Canadian Pacific and Canadian National operating specialized refrigerated container services.

I once watched a warehouse team in Winnipeg transload frozen peas from a rail car to trucks during -30°F weather. They were working faster than usual – not from efficiency, but because the loading dock was colder than the freezer!

The US Framework

The scale of US cold chain infrastructure is staggering. Major players like Lineage Logistics operate hundreds of temperature-controlled facilities nationwide, creating a network that can move products coast-to-coast without breaking the cold chain.

The US interstate highway system forms the arteries of this network, with an estimated 50,000+ refrigerated trucks moving at any given time. California alone generates more cold chain volume than most countries, with its agricultural exports requiring precise temperature management.

One interesting development I’ve watched evolve is the growth of specialized cold chain hubs in unexpected places. Salt Lake City has become a critical crossroads for western perishable distribution, while Harrisburg, Pennsylvania, has developed into a northeastern cold chain powerhouse due to its proximity to major population centers.

Cross-Border Complexities

Moving temperature-sensitive goods between the US and Canada adds several layers of complexity:

Border Delays

The worst enemy of the cold chain is time. Every minute a refrigerated trailer sits idling at a border crossing is burning fuel, adding emissions, and risking temperature excursions.

Smart shippers use programs like FAST/EXPRES and CTPAT to speed crossings, but delays still happen. I’ve had strawberry shipments sit for 5 hours during secondary inspections in the middle of summer – absolute hell for maintaining quality.

Regulatory Differences

Canadian and US food safety regulations have significant differences. A shipment that complies with USDA standards might not meet Canadian Food Inspection Agency requirements.

One mushroom grower I worked with had to maintain separate temperature protocols for US and Canadian shipments of the exact same product – 38°F for Canadian distribution and 36°F for US markets, based on different shelf-life validation studies required by each country.

Equipment Standards

While refrigeration technology is largely standardized, subtle differences in equipment specifications and maintenance practices exist. Canadian carriers often design systems to perform in more extreme cold, while US equipment might prioritize fuel efficiency in warmer climates.

Technology Keeping Things Cold

The technology monitoring today’s cold chain would have seemed like science fiction when I started in this industry:

- Real-time temperature monitoring with cellular and satellite connectivity

- IoT sensors that track not just temperature but humidity, ethylene levels, and door openings

- Blockchain systems recording temperature data at every step of the journey

- Predictive analytics that can spot potential refrigeration failures before they happen

A pharmaceutical client uses temperature trackers that cost $250 each to monitor high-value shipments. Excessive? Not when your truck contains $2 million worth of temperature-sensitive medications.

When Things Go Wrong

Despite best efforts, cold chain failures happen. The difference between professionals and amateurs is how they’re handled:

A top-tier Canadian meat exporter I worked with had temperature excursions on about 1% of shipments. What impressed me wasn’t the low failure rate, but their recovery protocol. They could divert a truck showing temperature problems to the nearest appropriate facility, conduct quality testing, and make disposition decisions within hours – often saving the majority of a load that would otherwise be lost.

North American cold chain partners have developed unprecedented cooperation networks for handling emergencies. I’ve seen competitors loan refrigerated trailers during equipment failures and share cold storage space during regional crises like ice storms or power outages.

The Last Mile Challenge

The final delivery stage remains the weakest link in both countries. Once products leave the highly controlled network of professional cold chain providers and enter local delivery systems, risk increases dramatically.

Canadian companies face particular challenges in northern communities, where infrastructure is limited. Specialized providers have developed innovative solutions like portable cold rooms that can be airlifted to remote locations.

In urban centers across both countries, the explosion of grocery delivery has created a whole new cold chain segment, with insulated bags, cooler boxes, and even temperature-controlled delivery vehicles becoming common sights.

The Future Is Getting Colder

The North American cold chain continues to evolve:

- Alternative refrigerants replacing environmentally harmful options

- Electric refrigerated trucks entering service in urban areas

- Modular cold chain systems allowing for more flexible capacity

- AI-driven temperature management systems that adapt to conditions in real-time

One Canadian startup is developing self-contained, solar-powered refrigeration units for trailers that can maintain temperatures for up to 24 hours without running the main engine – potentially revolutionary for reducing emissions and noise in urban deliveries.

The Human Element Remains Critical

For all the technology and infrastructure, the most important component of the cold chain remains people. The refrigeration technician who spots a potential compressor issue before failure, the driver who knows exactly how to adjust settings in changing weather, the warehouse worker who understands how to properly stack products for optimal airflow – these professionals are the true guardians of temperature integrity.

As one seasoned cold chain manager told me, “The thermometer tells you if you succeeded or failed. But it’s the people who determine which one it’ll be.”

Moving perishables across the second-largest country in the world and through the complex logistics networks of the United States requires extraordinary coordination, specialized knowledge, and constant vigilance. When it works – which is remarkably often – consumers never notice. And that silent reliability might be the cold chain’s greatest achievement.

Find more at Crown Web.